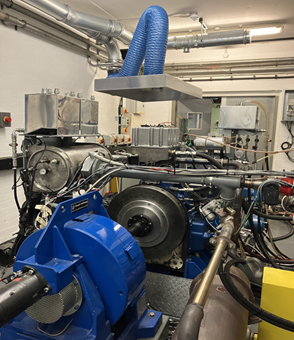

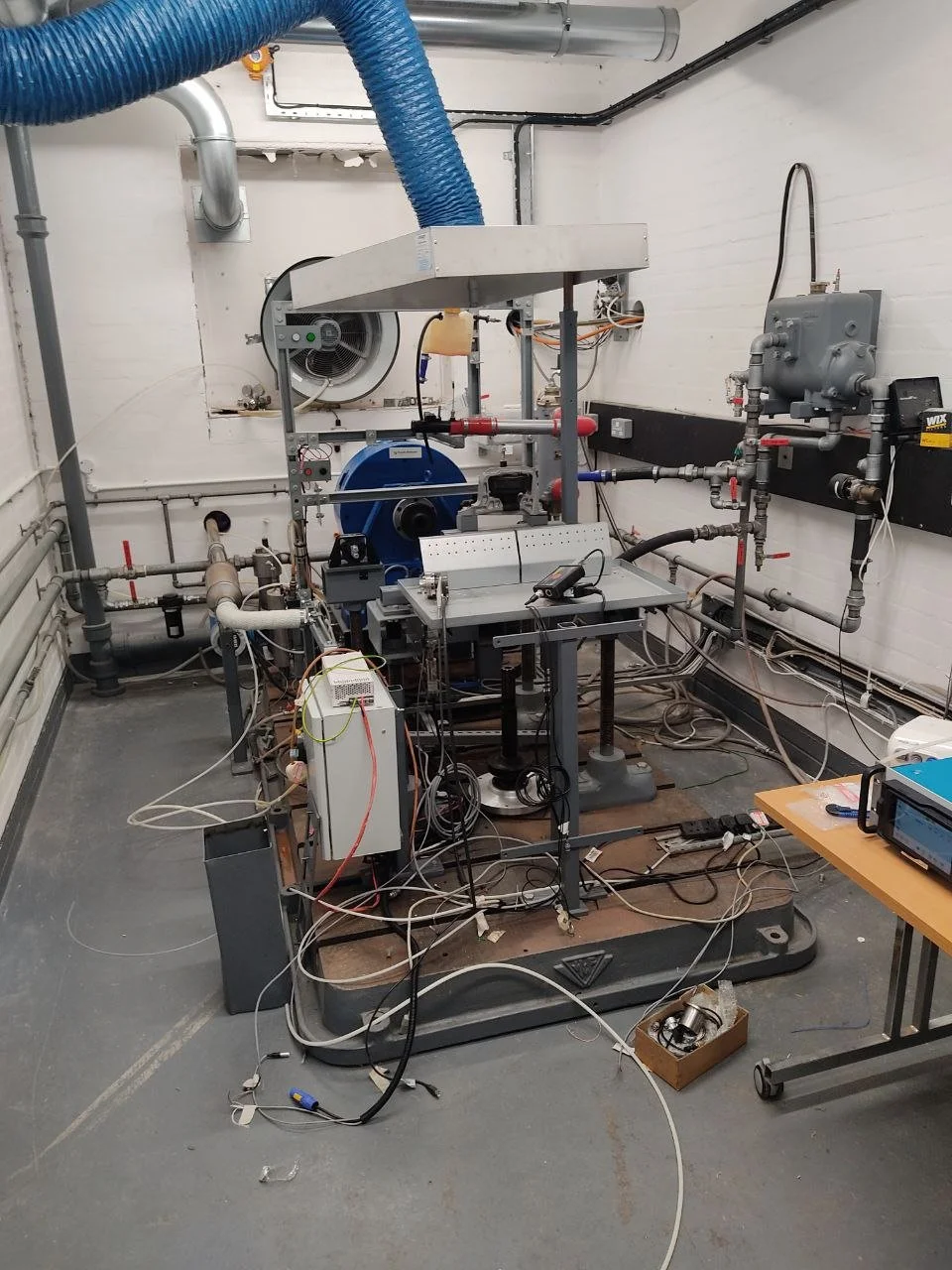

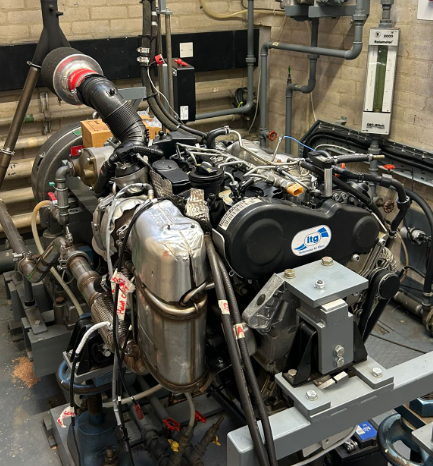

CAPF is equipped with state-of-the-art laboratories, specialist test facilities, and advanced simulation tools that support high-precision experimentation, system-level analysis, and collaborative industrial research. As one of the largest research groups in engine and fuel technologies in the UK, the Centre hosts one of the most extensive university-based engine development and testing infrastructures. This includes eight engine test cells; a comprehensive suite of combustion and emissions analysers—such as hydrogen, ammonia and engine exhaust gases analysers—and a full range of optical and laser diagnostic equipment for detailed fuel-injection and combustion studies. CAPF also maintains a diverse fleet of single-cylinder research engines ranging from 0.25 to 6.0 litres per cylinder, supporting investigations from small light-duty engines to large marine-scale systems. Five fully compliant hydrogen and ammonia fuelling and testing cells have been established following rigorous health and safety procedures.

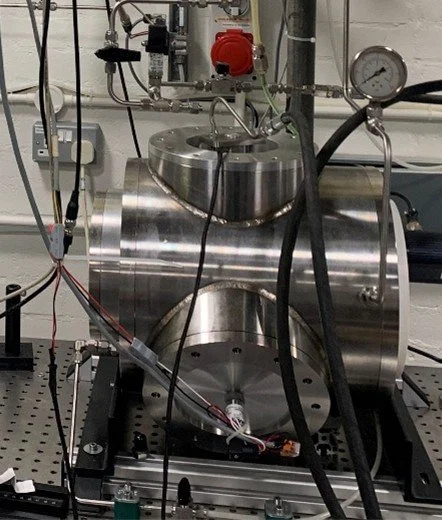

For fundamental research, CAPF operates spray constant-volume chambers, combustion bombs, fully transparent optical engines, and advanced laser measurement systems for in-depth studies of fuel injection, mixing, and combustion processes. Complementing its experimental capabilities, the Centre uses a full suite of simulation platforms for engine flow, spray, and combustion modelling, including zero-dimensional chemical kinetics codes, one-dimensional engine simulation software, and three-dimensional computational fluid dynamics tools.

Some of the testing facilities are listed below.